Our Automatic Cup Sealer range offers two powerful options: semi-automatic for streamlined operation and fully automatic for maximum efficiency.

Designed with user experience in mind, all models incorporate servo technology and an intuitive HMI, making them incredibly easy to operate and maintain. These versatile machines can perfectly seal a wide range of cup sizes. Plus, enjoy advanced functionalities such as auto-homing, precise production counting, and a high-quality brass heater for consistent, uniform heat. For detailed specifications and to discuss your specific needs, please contact our team.

Experience precise and versatile sealing with our Manual Combo Cup Sealer. Designed to handle HDPE, PP, and paper cups, this machine uniquely accommodates any two distinct cup sizes—from 75mm-80mm to 80mm-95mm and beyond. The integrated brass heater guarantees perfect lip sealing, while its digital temperature control system (featuring a thermocouple) allows you to precisely maintain sealing temperature for uniform heat distribution throughout your production run. This is a top model of the Manual Cup Sealer

For additional models and customization to meet your specific needs, please get in touch with our team.

Need to seal aluminum or PET cans?

Our Table Top Can Seamer is the solution! This small, powerful unit handles various can sizes, making it great for beverages, sauces, and syrups. Benefit from adjustable height, speed control, and guaranteed perfect sealing. Get in touch with us for more information.

Experience superior filling accuracy with our Piston Filler, an ideal solution for viscous and semi-viscous products such as curd, juice, sauce, pickle, yogurt, and syrup.

Operated by a robust pneumatic cylinder, this filler allows for mechanical volume adjustment, ensuring precise and consistent fills. For enhanced productivity, it can be easily synced with our automatic machines. For detailed specifications and to discuss how this filler can meet your production needs, please contact our team.

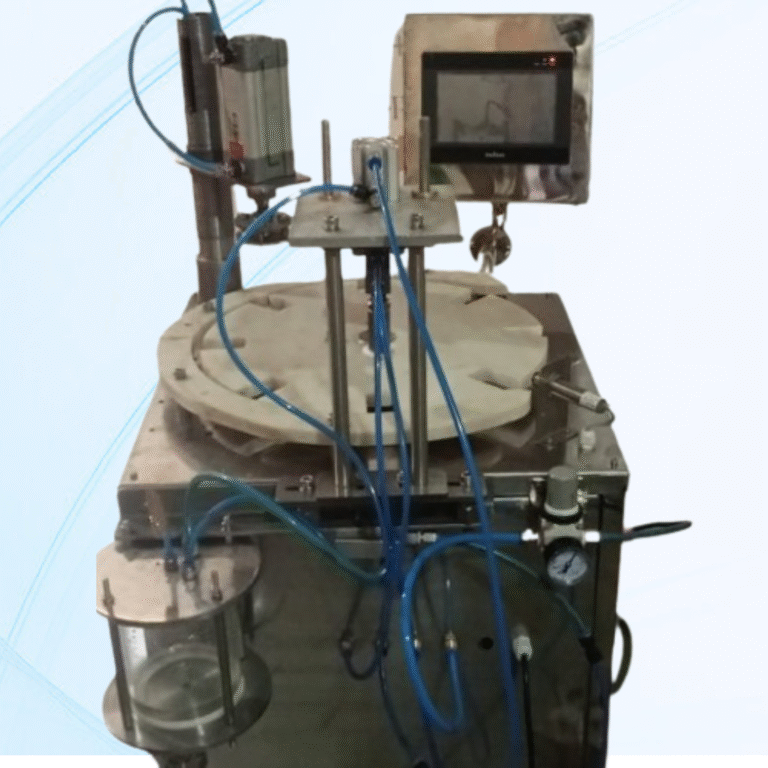

Streamline your production with our Automatic Perfume Filler and Capper Machine. This versatile solution is perfectly suited for accurately filling and securely capping small perfume bottles and attar containers, accommodating both PET and glass bottle types. Equipped with advanced servo technology and an intuitive HMI (Human Machine Interface), this machine offers precise control and ease of use. For comprehensive details and specifications, please contact our team.

Discover our comprehensive range of Bottle Crimpers, designed for reliable sealing across diverse sectors including perfume, beverage, and pharmaceutical industries.

We provide a wide selection of collets for different cap sizes, with the flexibility to create custom collets to meet unique requirements. This highly efficient machine operates pneumatically at 75 PSI, capable of sealing 8-10 bottles per minute.

Its design allows for seamless attachment to automatic production lines, ensuring ease of setup and operation.

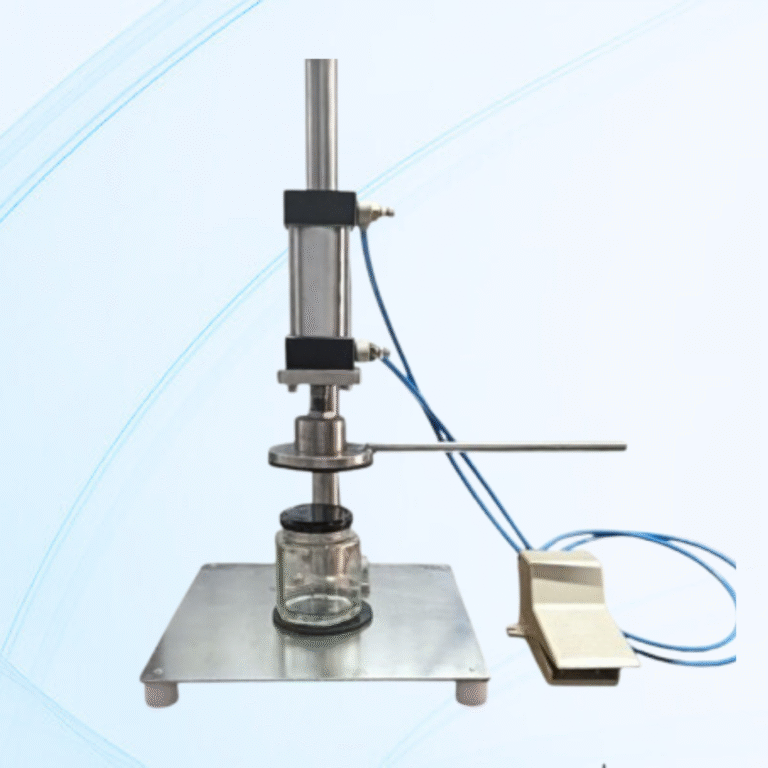

Ensure secure and efficient sealing for your products with our jar lid closing machine. Designed for versatility, it effectively closes lids on a variety of containers, including glass bottles and PET bottles. Pneumatic Lug Sealers plays an important role in takeaway outlets and small scale food industries.

Its pneumatic operation makes it remarkably user-friendly, allowing anyone to operate it with ease and without much effort.

Experience exceptional accuracy with our Gear Pump Filler, an ideal solution for precise volumetric dispensing of various liquids.

This versatile machine excels at filling products such as milk, juice, syrup, sauce, edible oil, engine oil, and other lubricants. Driven by servo technology, it ensures high precision and consistency, while the user-friendly HMI (Human Machine Interface) provides complete control and ease of operation.

For detailed specifications and to discuss how this filler can enhance your production, please contact our team.